Single-crystalline silicon solar cells

are among the most efficient and widely used technologies in the solar energy industry. They are known for their high purity and excellent performance in converting sunlight into electricity.

However, within the realm of single-crystalline silicon solar cells, there are various classifications based on different criteria, each offering unique advantages and applications.

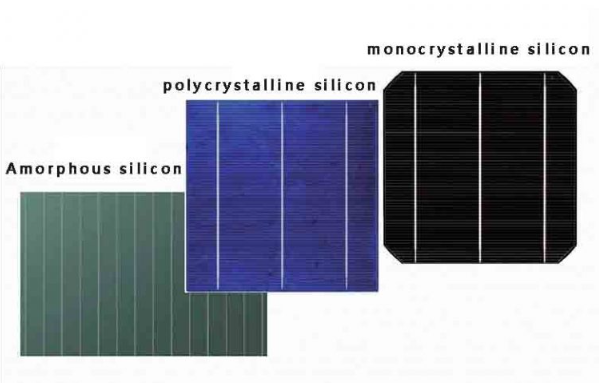

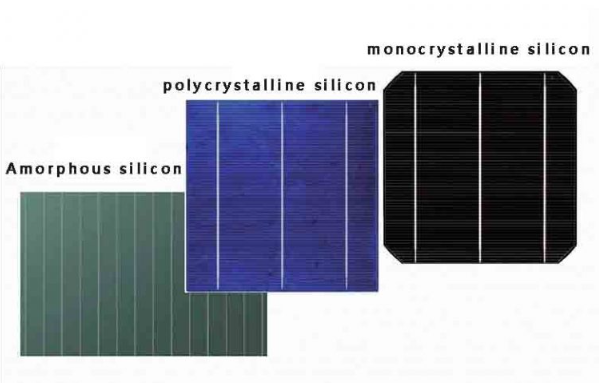

First. Crystalline Structure Classification

1. **Single-Crystalline Silicon Solar Cells**:

These cells are fabricated using high-purity single-crystalline silicon ingots, resulting in high-efficiency solar cells with stable performance. They are renowned for their high conversion efficiency and durability, making them a popular choice for residential and commercial solar installations.

2. **Polycrystalline Silicon Solar Cells**:

In contrast to single-crystalline cells, polycrystalline cells are made from multiple silicon crystals, resulting in a lower-cost alternative. While polycrystalline cells generally have lower efficiency compared to their single-crystalline counterparts, they remain a cost-effective option for large-scale solar projects.

3. **Amorphous Silicon Solar Cells**:

Amorphous silicon solar cells utilize non-crystalline silicon as the base material, commonly used in thin-film solar panels. Although they typically have lower efficiency compared to crystalline silicon cells, amorphous silicon cells offer flexibility and lightweight characteristics, making them suitable for applications where weight and flexibility are critical factors.

Second. Technological Classification

1. **PERC Cells (Passivated Emitter Rear Cell)**:

PERC cells employ phosphorus-doped P-type single-crystalline silicon with a passivation layer on the rear side. This technology has become mainstream due to its enhanced efficiency and reliability, making it a preferred choice for solar panel manufacturers.

2. **TOPCon Cells (Tunnel Oxide Passivated Contact)**:

TOPCon cells utilize a tunnel oxide passivated contact layer to achieve improved efficiency and reduced recombination losses. While still emerging, TOPCon technology shows promising potential for further efficiency gains in the future.

3. **HJT Cells (Heterojunction with Intrinsic Thin layer)**:

HJT cells combine N-type single-crystalline silicon with thin layers of intrinsic amorphous silicon. This advanced technology offers higher efficiency and better environmental stability compared to traditional solar cell designs.

Three. Dopant Type Classification

1. **P-Type Single-Crystalline Silicon Cells**:

These cells are doped with boron to create P-type conductivity, commonly used in PERC and TOPCon cells due to their superior performance and stability.

2. **N-Type Single-Crystalline Silicon Cells**:

Doped with phosphorus, N-type cells offer several advantages including immunity to Light-Induced Degradation (LID), making them an attractive option for certain applications where efficiency and reliability are paramount.

In summary, single-crystalline silicon solar cells can be classified based on crystalline structure, technological advancements, and dopant type, each offering distinct characteristics and applications. As the solar industry continues to evolve, advancements in single-crystalline silicon technology are expected to drive further improvements in efficiency, reliability, and cost-effectiveness, contributing to the widespread adoption of solar energy worldwide.

Karstsolar is a professional solar panels manufacturer.

We work with you back-to-back to provide high-quality and affordable solar modules.

We partner with controller manufacturers, microinverter manufacturers, and bracket manufacturers. We have a strong supply chain group and provide products including solar panels, inverters, etc. Inverters, balcony systems, etc. Please reply to our email and tell us what solar product you need now and try it today: marketing@karstcom.hk

Very interesting topic, thanks for putting up.Blog monetyze