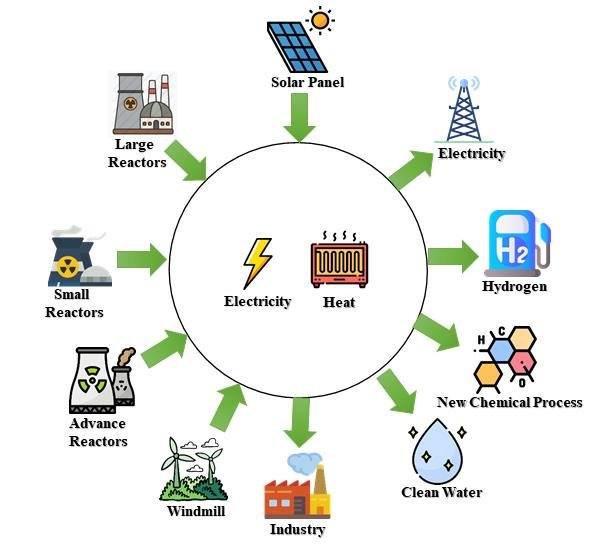

The energy-saving potential of solar energy in industrial production is huge. It can not only provide clean and sustainable energy for industry, but also significantly reduce energy costs and carbon emissions of enterprises.

Industrial production often requires large amounts of electricity and heat. Some large companies even build solar power generation systems as infrastructure to achieve self-sufficient energy supply.

Power supply and thermal energy utilization:

Through efficient solar photovoltaic power generation systems, solar photovoltaic power generation systems can directly convert solar energy into electrical energy to provide part or all of the power needs for industrial facilities. Solar energy can be converted into electrical energy to provide green energy for factories, workshops and production lines.

Industrial thermal system:

Solar industrial thermal system absorbs solar radiation through a collector, converts light energy into thermal energy, and stores it using water as a medium for direct or indirect utilization in various production processes. The water temperature of this kind of system can reach 80℃-90℃ in spring, summer and autumn, and can be directly used in most thermal processes such as slaughtering, canning, brewing, noodles, beer, vegetable processing, printing and dyeing.

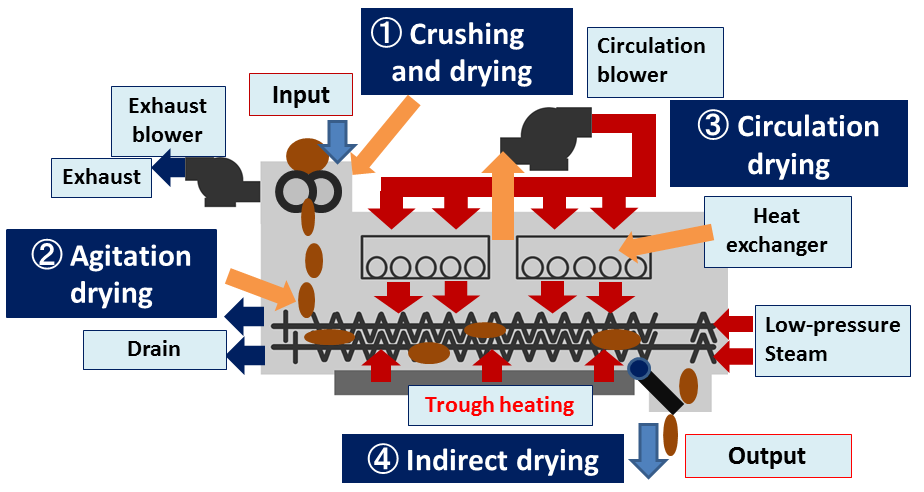

Process heat and drying:

Many industrial processes require high-temperature thermal energy to process raw materials or dry products. Solar collectors can effectively capture solar radiation and convert it into high-temperature heat energy for industrial heating processes, replacing traditional coal or gas heat sources and reducing production costs and carbon emissions. Solar thermal energy systems can be used to provide thermal energy needs in hot water, heating or cooling processes, saving traditional fuel consumption.

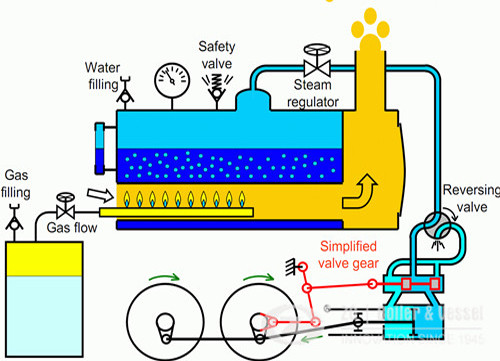

Industrial steam:

The trough solar thermal collection system can provide steam for industrial production, meet the characteristics of steam used by industrial enterprises, and optimize adaptability, economy and stability. In addition, solar industrial application technology can directly heat cold water into high-temperature steam, which can fully meet the requirements of chemical production.

Energy efficiency improvements:

The application of solar energy technology can promote energy efficiency improvements in industrial production. For example, in terms of lighting, using solar photovoltaic power generation systems to power LED lighting can reduce energy consumption; in terms of transportation and storage, solar energy can be used to charge electric vehicles or power internal logistics equipment such as stackers, reducing the need to use traditional energy.

Reduced environmental impact:

Adopting solar energy reduces dependence on fossil fuels, thereby reducing greenhouse gas emissions and the release of other environmental pollutants. This helps industrial production become more sustainable and environmentally friendly in the context of increasingly severe global warming and environmental protection issues.

The following are some specific application cases:

- Denmark’s solar district heating market:

- Denmark is one of the first countries in the world to promote solar district heating. The installation of collectors in its large-scale solar heating systems accounts for 80% of the world’s such systems, demonstrating the importance of solar energy. Huge potential in industrial and residential heating

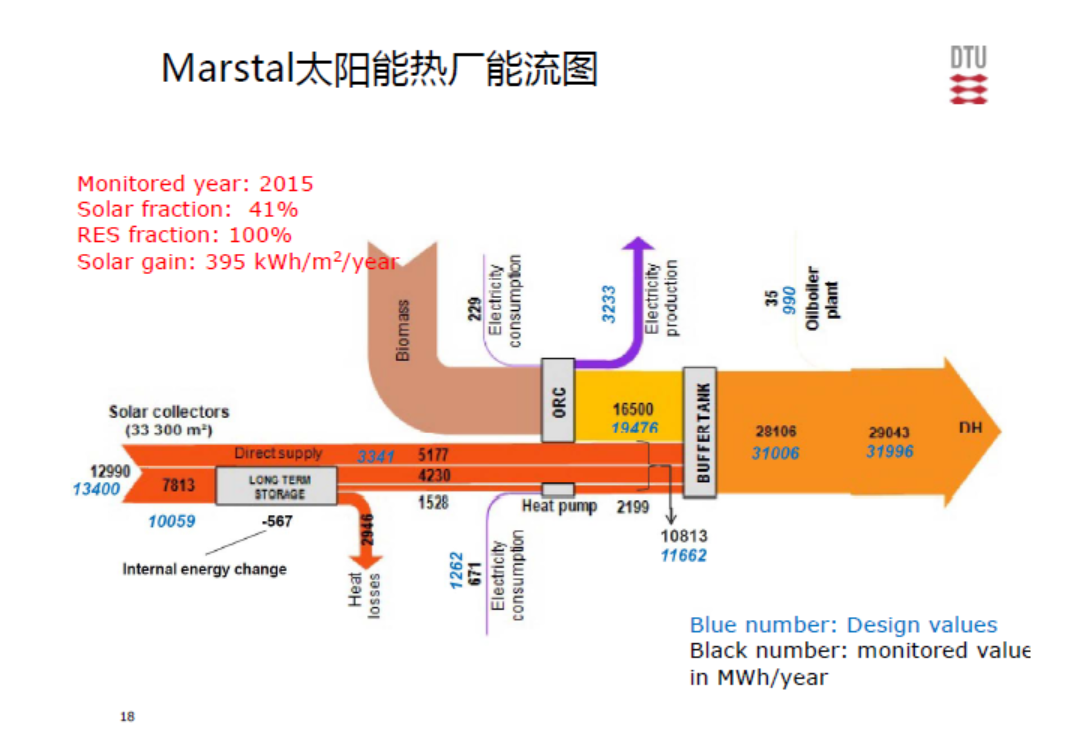

- Marstal Solar Thermal Plant Energy Flow Diagram>>>

- U.S. wastewater treatment plants:

- In the United States, many wastewater treatment plants use solar technology to improve energy efficiency and reduce energy consumption in the water supply and water treatment processes. For example, operating costs are significantly reduced through the application of new technologies and renewable energy.

- <<<Hill Canyon Wastewater Treatment Plant 584 kW DC Solar Photovoltaic System

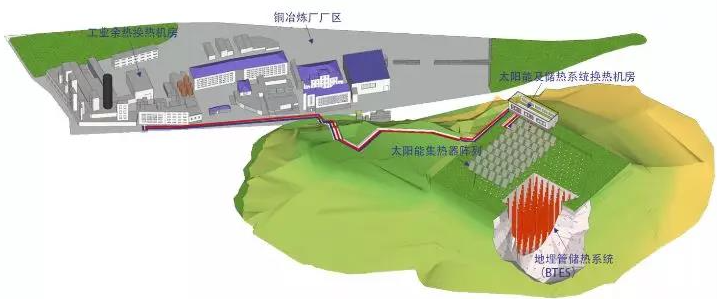

- Jinjian Copper Factory in Chifeng, Inner Mongolia, China:

- Tsinghua University and Huaye Sunshine cooperated to implement the “industrial waste heat + solar energy” thermal storage heating demonstration project at Jinjian Copper Factory in Chifeng City, Inner Mongolia. This project uses solar cross-season soil thermal storage heating technology, using solar heat collection and industrial waste heat as the core heat energy source to achieve an efficient heating system.

- Schematic diagram of industrial waste heat-solar inter-seasonal heat storage for urban central heating demonstration project>>>

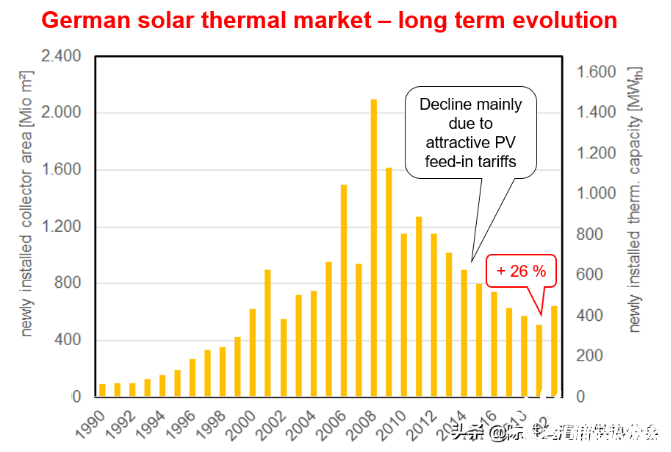

- SDH plants in Germany:

- As of the end of 2020, there were 41 solar district heating (SDH) plants in operation in Germany, with a total capacity of approximately 70 MWth. These factories use solar energy to heat industry and services, significantly improving energy efficiency.

- <<<German solar thermal market – long term evolution

In summary, the application of solar energy in industrial production can not only significantly save energy costs, but also reduce environmental load and promote sustainable industrial development. With the advancement of solar energy technology and the reduction of costs, its application prospects in the industrial field are very broad. With the advancement of technology and reduction of costs, the potential of solar energy in industrial energy saving will be more fully tapped and utilized.

ENERGIZING YOUR LIFE

Karstsolar, based in Shenzhen, is a company dedicated to solar panel production and international trade. Founded in 2009, Karstsolar boasts extensive experience in solar technology and a remarkable track record in global market expansion. We take pride in delivering efficient and reliable solar solutions to clients worldwide.